Abstraction

Not solely the omnigenous usage of metal material or as the conductor medium be performed, that particularly issues which come into notice for the metal material are their exposure to every potential destruction and deteriorate environment hence enormous pecuniary loss resulted in.

Lately, satistics shows there about 1 million tons above narrated or relative. Therefore, the research of their protection has been the momentous task and the pressing need for engineers and scientists.

Surface Anti-corrosion Treatment

Means apply kinds of protection on the surface of mental to quarantine itself form the corrosives environment and restrain the progress of or reduce the adjoining between corrosive media and metal surface to avoid or mitigate the corrosion situation.

The Reason of Metal Corrosion

Produced by industrial pollution and plenty exhausted fume emission of vehicles, the gaseous, minute particle corrosiveness sulfides as well as chloride teemed within the air and made the major reason of metal eroding.

Anti-corrosion R3, Anti-corrosion R3,

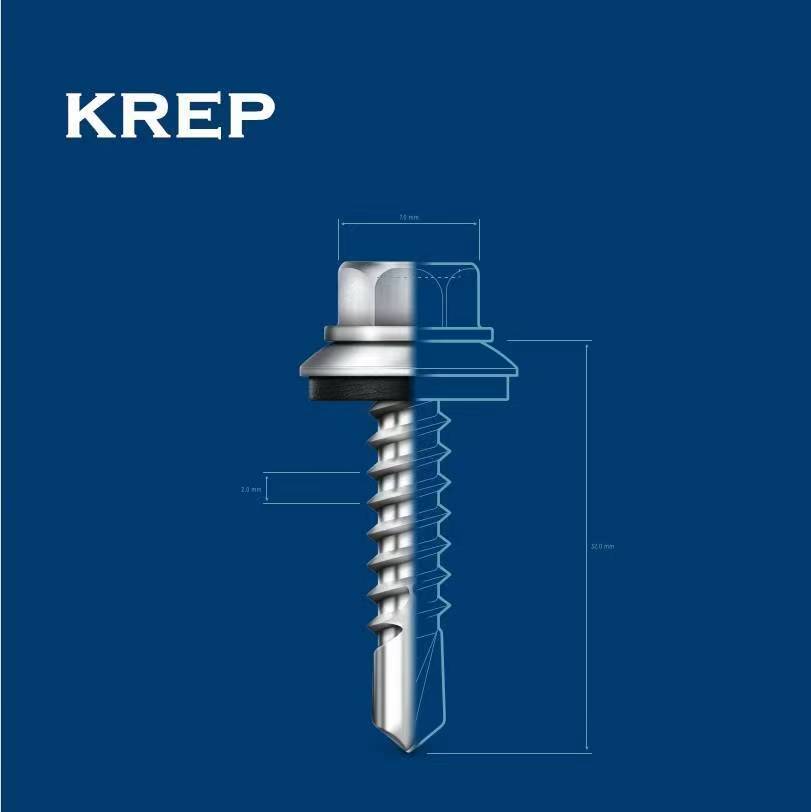

This advance technology now are all available to apply to screw & nuts, helps to defense the corrosion once exposure to the sever marine, industrial, critical and air pollution as well. To determine the type of usage and cost, we have contained total solution for your essential.

Typical appearance of heads of fasteners using the salt-spray test

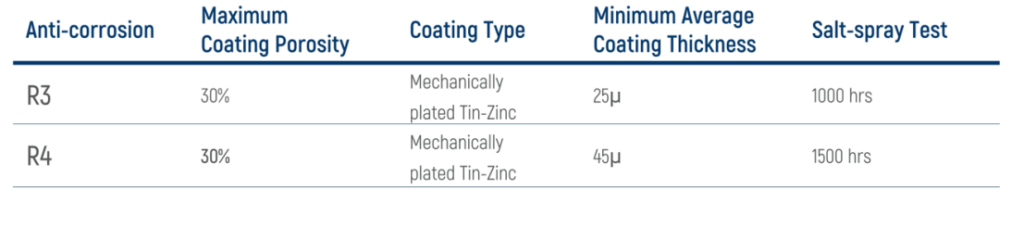

Anti-corrosion R3 & R4 is a superior corrosion resistant fastener finish. When a fastener is treated with Anti-corrosion R3 & R4, its entire surface is covered with polymer coating not susceptible to oxidation. Anti-corrosion R3 & R4 outperfrm all other existing electro-plating and prevent corrosion caused by chemical reaction between dissimilar metals. Anti-corrosion R3 & R4 create an attractive, metallic-grey finish that provide an excellent base surface for color matching paint. It is compatible with all painted and metal-coated surface.

Anti-corrosion Fasteners Deemed to Comply

Self drilling screws shall exhibit the minimum properties appropriate to the intended usage as given in below.